There are many factors that contribute to give a craft beer its character and they are not only related to the ingredients, the recipes or the production method, but they are also connected to other, diverse aspects, such as the size of the company, a strong territorial characterization, constant experimentation and the use of the highest quality ingredients.

The first big difference between craft beers and industrial beers is, of course, in the production process that in industrial beers includes two phases that do not apply to craft production: pasteurization and pre-bottling filtration.

These two phases are needed to obtain a longer storage period and to uniform the taste in the industrial products, eliminating any natural variations, which, instead, remain in craft beer, enhancing all the flavors and aromas of its ingredients. Moreover, precisely because of the uniqueness of their production, craft beers do not have added carbon dioxide: since they are not being pasteurized, the yeasts that remain "alive" in the beer produce themselves, both naturally and with the addition of sugar, the carbon dioxide of which they are rich.

Now let's see, in detail, what are the various phases of the production process that, at Birrificio San Quirico, we adopt in the production of our craft beers.

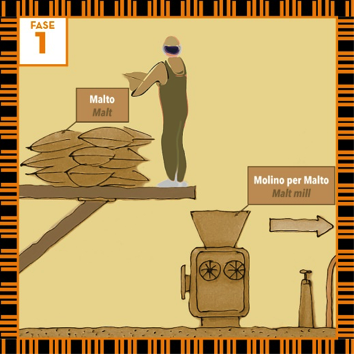

GRINDING

The first phase in the production of a craft beer consists of a light GRINDING or a "weak" crushing of the barley malt. This is a delicate and fundamental operation, which naturally affects the yield and quality of the final product and which requires first of all a cereal with the right degree of crumbliness. The fineness of the grinding affects the final yield: the coarser it is, the lower the beer yield. In craft beers, in which the grinding is coarse also due to a less fine filtration, the yield is in fact lower.

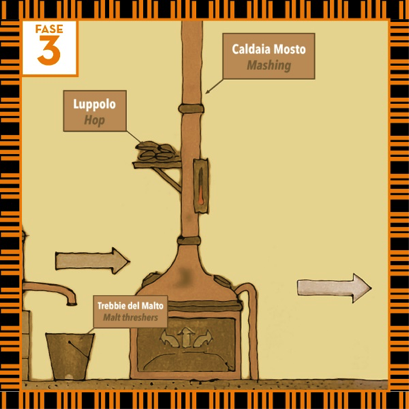

MASHING AND FILTRATION

The MASHING process takes place in the brewhouse in special vats. Water is added to the crushed malt according to precise proportional ratios: the malt is first mixed with warm water and then brought to higher temperatures, about 75° C. With this operation the starch present in the malt is transformed into fermentable sugar obtaining a protein-rich sugar solution called must. The biochemical reaction of mashing produces sugars of varying complexity, which will determine the characteristics of the final product: body, alcohol content and consistency of the foam.

The FILTRATION consists in separating the must, i.e., the liquid fraction of the saccharified compound, from the solid residue (called "beer threshing"). The filtered liquid is then collected in the boiling boiler. During filtration, the threshing is also washed which allows the extraction of additional amounts of sugars.

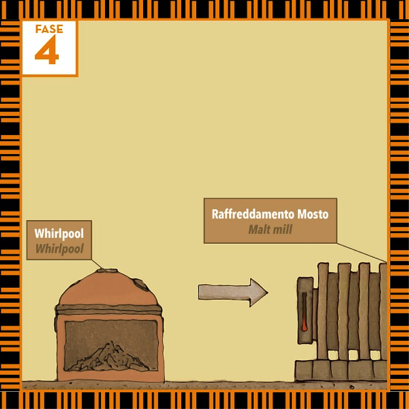

BOILING, WHIRPOOL AND COOLING

The filtered must is placed in a special boiler and subjected to BOILING. During the process, hops are added in the quantities according to the various recipes and which, due to the effect of the heat, trigger their bitter action, thus giving its characteristic bitter taste to the beer. During cooking, in addition to hops, other natural flavorings are added. Boiling also has a sterilizing effect and, with the evaporation of water and the consequent concentration of the must, increases the sugar content.

The solid part is removed from the hot must, through a WHIRLPOOL effect (reel). The must is placed in the Whirlpool vat in which the circular movement pushes the liquid part towards the walls and the solid part towards the center, separating them.

Before starting fermentation, the must has to be subjected to a rapid COOLING. It is therefore fed into a heat exchanger that lowers the temperature to about 20° C with a counter-current water system.

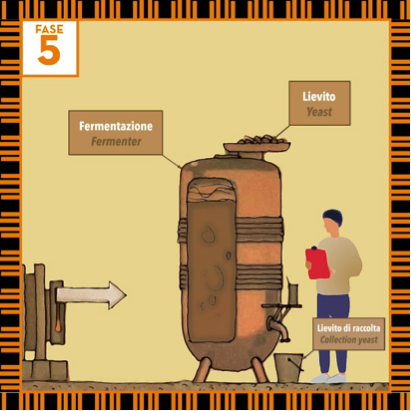

FERMENTATION AND MATURATION

The cooled must is sent to the FERMENTATION vats where the inoculation of brewer's yeast (Saccaromyces Cerevisiae) is carried out, which will begin to transform the sugars of the must into ethyl alcohol, releasing carbon dioxide. It is the yeasts that transform the must until it takes on the chemical-physical and organoleptic profile of the beer to drink.

Each brewer can adopt – for the fermentation process – different techniques, which depend on the choice of low or high fermentation yeasts, the temperatures and the structural characteristics of the tanks.

MATURATION: at this stage the must is kept at a constant temperature according to the type of yeast selected. Usually, when producing top-fermented beers, the temperature is kept constant at 20°C until the fermentation is completed when all the sugar is turned into alcohol.

The maturation allows the drink to achieve greater clarity and to balance the sweetness of the malt, the bitterness of hops, the alcohol content and the carbonation. Each type of beer matures at different times and, generally, bottom-fermented light beers require a longer period of maturation.

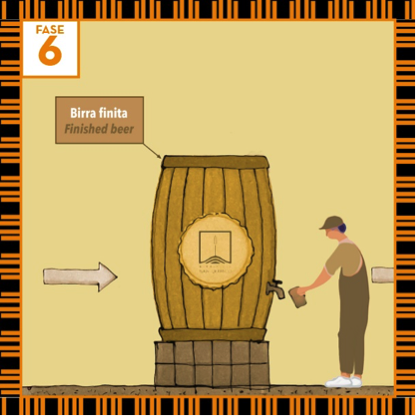

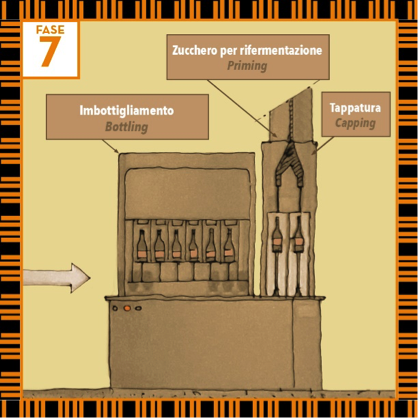

BOTTLING

After maturation, the beer can be bottled or kegged by adding again a very small amount of sugar before closing the container in order to allow a second fermentation in the bottle or in the keg (similar to what happens in sparkling wines or champagnes, with the so-called "classic method"). This way the fermentation continues even inside the bottle, releasing carbon dioxide able to carbonate the product in a natural way and giving that softness typical of our craft beers. After about 60 days from bottling, the refermentation in the bottle will be completed and the beer, properly carbonated, will be ready to be consumed.

Italiano

Italiano